Equipment

Equipment

| NO. | Item | Specification |

|---|---|---|

| 1 | SAW PANEL WELDING M/C (Ⅰ,Ⅱ) |

- Welding Speed : Max. 1000mm / min - 150Pcs/Day_Tube 12M, (Based On 8 Hour Working) - Welding Torch : 1500A-12 Pole - Tube Size : 38.1 Ø / 45 Ø / 50.8 Ø / 76.2 Ø - Welder Specification : LINCOL 1500A SAW Welder 12ea - Conveyer Exchanger System - Max Length : 20M |

| 2 | PANEL BENDING M / C |

- Roller Size : 1,820mm - Main Cylinder : 300 Ø x 550ST - Bending Mold : 38.1 Ø / 45Ø / 50.8Ø / 76.2Ø |

| 3 | FIN STRAIGHTENER |

- Include Uncoiler - Include Wire Brush |

| 4 | TUBE BLAST M/C |

- Automatic Conveyor Type - Shot Blast Specification : SP10 - Shot Blast Capacity : 160 Pcs/Day |

| 5 | MANIPULATOR SUBMERGED WELDING MACHINE | - Pressure Vessel Inside & Outside Welding |

| 6 | TURNING ROLLER (100 Ton) | - Max 100 Ton Handling |

SAW PANEL WELDING M/C (Ⅰ)

SAW PANEL WELDING M/C (Ⅱ)

PANEL B / D MACHINE

FIN STRAIGHTENER

TUBE BLAST M / C

MANIPULATOR SUBMERGED WELDING MACHINE

TURNING ROLLER (100TON)

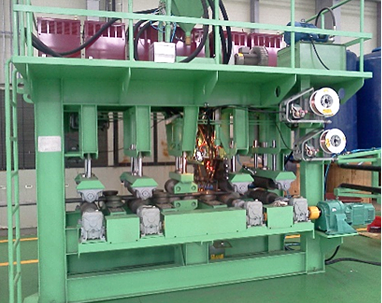

FINNING M/C_F-BAY

| NO. | Specification | |

|---|---|---|

| 1 | TUBE DIAMETER | Min. Ø 19.1mm ~ Max. Ø 114.3mm |

| 2 | TUBE LENGTH | Min. Ø 4000mm ~ Max. Ø 23000mm |

| 3 | FIN WIDTH | Min. Ø 8mm ~ Max. Ø 25.4mm |

| 4 | FIN THICKNESS | Min. Ø 8mm ~ Max. Ø 25.4mm |

| 5 | RAW MATERIAL |

- Carbon Steel - Heat Resistant Alloy Steel - Stainless Steel (Chrom-Nickel Steel) |

| 6 | FIN PITCH | 1 Fins / Inch ~ 8.63 Fins / Inch (25.4mm ~ 2.941mm) |

| 7 | TUBE ROTATION SPEED | Finning RPM Max. 1200 rpm (High Speed) |

| 8 | OSCILLATION OUTPUT | 300 Kw X 450 KHz |

| Description | Need Q’ty | |

|---|---|---|

| POSSIBLE FABRICATION QUANTITY OF FINNING (PER 1 YEAR) |

Quantity of Finning Machine | 2 UNIT |

| Piece of Possible Production (per 1 day) | 200 piece | |

| Work Day (based on 1 month) | 25 days | |

| Possible Quantity of Finning (per 1 year) | 60,000 piece | |